Suitable materials for temperature and chemical resistance are vital for various industries. Some of these industries include the semiconductor industry, the power industry, and the automotive industry.

Other important sectors include the packaging industry and the manufacture of chemical reagents and cleaning agents. While these industries all require parts with good chemical and temperature resistance, they also require a range of other factors.

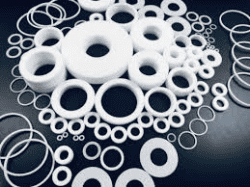

The main factor that affects the durability of a material is its substance. In particular, its molecular structure. When a material is subjected to a chemical attack, the polymer bonds may break down, causing the material to experience rapid degradation. This can cause damage to the surrounding parts, as well as reduce functionality. When you need a strong product that is resistant to heat and chemicals, consider Silicone moulding UK from a site like www.meadex.co.uk/

When choosing a polymer, it is crucial to determine if it has good chemical and temperature resistance. This will help to ensure that it will remain functional in its application. It is also essential to understand that different types of chemicals have other effects. For example, sulphuric acid can erode the surfaces of certain types of plastics.

Chemical and temperature resistance also depends on the material’s chemical composition and the environment in which it is used. For example, water-based chemicals will not affect a polymer that is resistant to acetone. On the other hand, a non-chemically resistant material will suffer from blistering, brittleness, and mechanical deformation.

Materials that are chemically and temperature-resistant can be very expensive, though. They also have to be carefully chosen. These are especially important in applications that involve high-temperature environments. Various chemical agents can damage plastics with low chemical and temperature resistance, and additionally, they can have reduced impact toughness and tensile strength.

PVDF is an excellent material for a wide variety of applications. It provides superior chemical and temperature resistance and is available in sheet, rod, and tubing form. High-purity homopolymer PVDF does not allow the growth of biological impurities and is non-leaching.

Thermoplastics are a commonly used type of plastic. These materials have a wide range of uses, including chemical media storage, chemical processing, and chemical packaging. They are also used in the manufacturing of tooling and parts.

Another advantage of heat-resistant plastics is their thermal stability. Various industries rely on these materials to provide a high-performance alternative to metal. Heat-resistant plastics are also capable of corrosion and electrical resistivity.